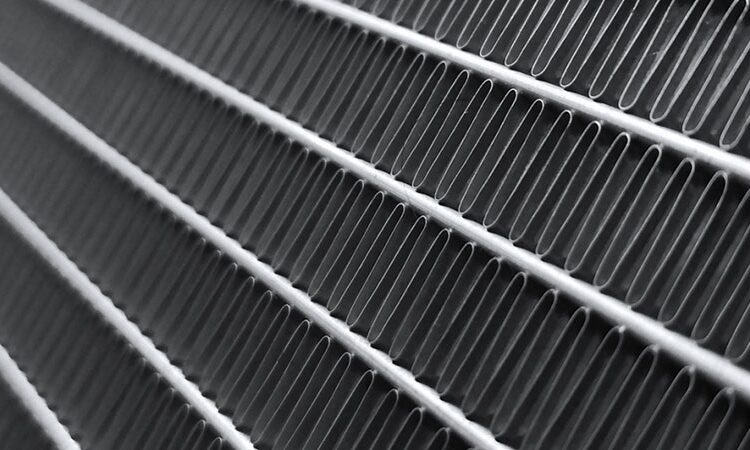

The micro channel heat exchanger (MCHE) is ideal for use in both residential and commercial air conditioning systems. It is refrigeration equipment driven by energy efficiency and devaluation of the refrigerant. With MCHE, you get a smart minimalist design, all aluminium which is not only lightweight but also prevents galvanic corrosion. Aluminium construction makes it one of the most sustainable solutions on the market due to its high strength, sealed design and recycled materials.

What are the benefits of using the micro channel heat exchanger?

The benefits of micro channel heat exchangers are given by,

Low air pressure drop:

The low air resistance is also another important advantage of micro-channel heat exchangers compared to traditional HVAC coil designs. The micro-channel heat exchanger shows 60% less pressure drop on the airside, thus reducing fan power and noise levels generated by the fan due to the low resistance, thus increasing airflow through the micro-channel heat exchanger.

Approaching temperature:

The same characteristics that make the micro-channel heat exchanger highly efficient. It also allows access to a similar temperature between air and refrigerant, which is critical in HVAC applications.

Compactable:

A micro-channel heat exchanger with a tube width of 32 mm provides almost the same performance as a 6-row finned tube heat exchanger with the same face area. Therefore, smaller and cheaper microchannel heat exchangers can be used. Depending on usage, this may allow additional heat exchange surfaces leading to unprecedented efficiency and energy efficiency of an HVAC system.

Low cooling cost:

The internal volume of the micro-channel heat exchanger is much smaller compared to the traditional finned tube heat exchanger. This is achieved by using microchannel tubes less than 1 mm in diameter, while the diameter of the copper tubes used in plate heat exchangers is much higher. With the introduction of a limited approach to the use of HFC refrigerants and the advent of the much lower cost GWP. Refrigerants with zero chance of destroying the ozone layer and reducing the amount of heat exchangers. It makes the equipment more ecologically safe.

Strong construction:

In contrast to traditional finned tube heat exchangers, the core of the micro-channel heat exchanger is very robust. The fins of the micro-channel heat exchanger are well protected from bending and mechanical damage.

Lightweight:

The lightweight, compact size and reduced internal volume of the all aluminium micro-channel heat exchanger are the factors that contributed to the dramatic increase in popularity in the automotive industry. These characteristics are of great importance in the field of cooling systems, especially when it comes to mobile cooling systems. The reduced size and weight not only resulted in lower shipping and handling costs but also the lower labour cost.

Reduce equipment costs:

The advantages discussed above of micro channel heat exchanger reduce the overall cost of the device, which benefits from a smaller heat exchanger size and reduced refrigerant cost. It must also be noted that refrigeration units using micro-channel heat exchangers allow the removal of some elements. For example, direct expansion systems do not require a refrigerant supplier. These are components that are both fragile and expensive in terms of labour.